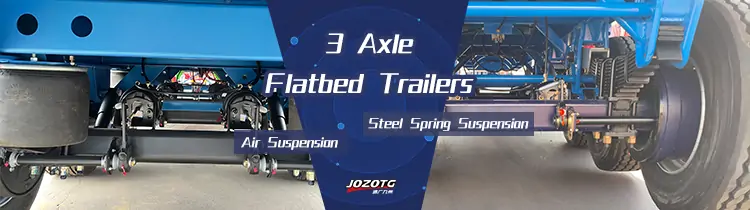

Mechanical (leaf-spring) suspension

The main appeal of a leaf-spring system is its low up-front price, straightforward construction and comparatively cheap upkeep. Unfortunately, the springs are bolted rigidly to the frame, so every pothole and expansion joint is transmitted straight into the chassis. Years of this hammering accelerate metal fatigue and can crack frame rails. Because the springs barely absorb energy, liquid in a tanker surges violently, stressing internal baffles and risking damage to sensitive or fragile cargo. When a wheel drops into a deep rut, the axle can rebound hard enough to lift the tyre off the ground, instantly robbing the driver of traction and braking power – a clearly dangerous situation. Finally, ride height is fixed; there is no way to raise or lower the trailer for loading docks or rough terrain.

When a trailer is specified for a 20-year design life and a million-kilometre duty cycle, the choice between leaf-spring and air suspension is no longer a matter of purchase price alone; it is a question of total cost of ownership, residual value and brand reputation. Leaf-spring systems remain the baseline: a stack of tempered steel blades bolted to a solid hanger. They are inexpensive to forge and simple to replace, yet every dynamic event—an 80 km/h impact with a 40 mm pothole, a 0.3 g braking input or a fully laden corner on a rough quarry road—generates a shock wave that travels un-attenuated through the spring seat, the sub-frame and ultimately into the tank barrel. Finite-element analysis carried out by our R&D centre shows stress peaks of 380 MPa at the fifth wheel interface after only 200 000 km, a figure that already exceeds the fatigue limit of S355 steel. The same study records peak vertical accelerations of 14 g on the upper baffle of a 42 000 l aluminium tanker, sufficient to loosen weld toes and initiate circumferential cracks that later become costly warranty claims. Because ride height is cast in steel, operators cannot lift the chassis to clear yard debris or lower it to slip under a 3 600 mm loading rack; the trailer is locked into a compromise geometry that erodes tyre life and amplifies driveline vibration.

Air suspension

Air suspensions cost more at the outset, are more complex and demand better-trained technicians. In return they deliver major advantages. The air bellows filter out most road shocks, dramatically reducing fatigue on the frame, tank shell and other components and therefore lengthening vehicle life. The smooth ride keeps liquid movement to a minimum, protecting both the tank’s internal structure and high-value or easily spoiled products. Because the air springs keep the axle in constant contact with the ground, tyre grip is better, braking distances shorter and mountain-road safety markedly improved. Ride height can be raised or lowered manually or automatically, speeding up loading operations and giving extra clearance if a tyre goes flat.