Over the last decade, the African heavy-haul sector has quietly converged on a single workhorse: the 13.75 m, three-axle flatbed semi-trailer. What began as a scattered demand for “something strong enough for laterite roads” has evolved into a de-facto regional standard that balances legality, durability and lifecycle cost. Engineers now speak of an “African load case” that is markedly different from the Euro-centric EN 12642 or North-American DOT profiles: higher peak loads per square metre, poorer surface regularity, extreme temperature cycling and a maintenance ecosystem dominated by roadside workshops rather than franchised dealers. The specification that has emerged is therefore not a marketing accident; it is the mathematical optimum for moving 28–30 t of containerised, bulk or break-bulk cargo over 500 000 km without a major chassis intervention.

The structural core is a cold-formed, single-piece “I” beam fabricated from Q345B structural steel. At 500 mm deep, with a 14 mm top flange, 16 mm bottom flange and 8 mm web, the section modulus reaches 1 050 cm³ per side rail—roughly 35 % higher than the light-duty 12 m platforms common in Asian intra-city work. This reserve of bending strength is intentional: it keeps flange stresses below 200 MPa when the trailer is hit with a 12 t point load from a 20 ft container corner casting on a potholed road. Finite-element studies commissioned by two Nigerian fleet operators show that peak stress occurs at the 0.4 L position (just ahead of the centre axle), exactly where the African specification places a 300 mm wide reinforcement plate. The same modelling exercise revealed that a European 10 mm web/12 mm flange design would exceed the yield limit at only 22 t payload under identical boundary conditions. In other words, the heavier African beam is not over-built; it is correctly built for the duty cycle.

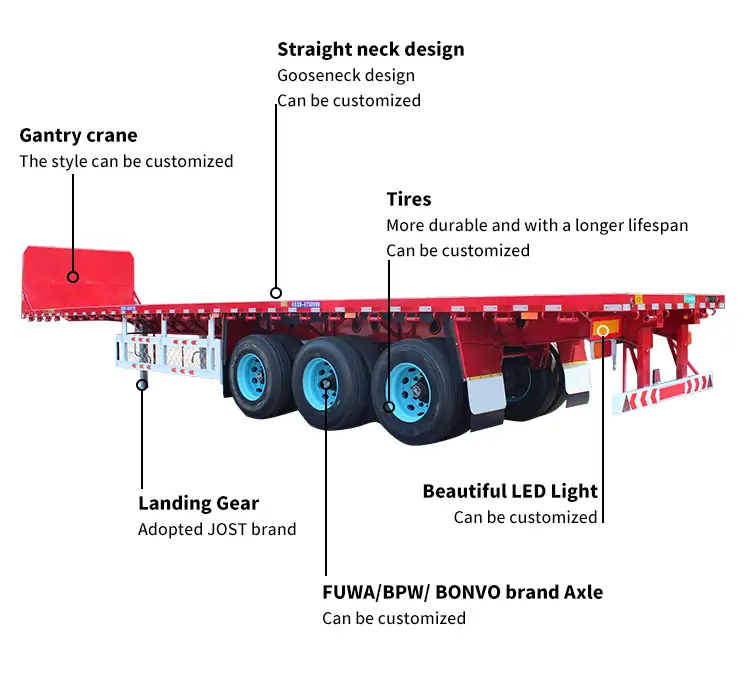

Top-Selling Flatbed Semi-Trailer Specifications for Africa

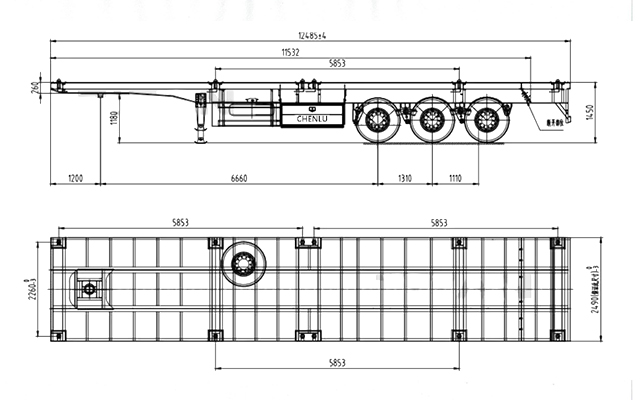

| Overall (L*W*H) | 12500*2500*1530mm |

| Frame | Material:High strength low alloy Q345 steel |

| Main beam | Main beam height:500 mm |

| Floor | 3 mm checkered plate |

| Side beam: | 16# channel steel |

| Axle | 3*13 tons FUWA/BPW axles |

| Tire | 12R22.5 Tire,10 pcs |

| Rim | 900*22.5, 12 pcs |

| Braking System | 6 Double-chamber , Duel Line Brake System |

| Suspension | Air spring suspension |

| King Pin | 2″ (50#) or 3.5″(90#) high tensile steel bolted type |

| Landing Leg | 28T landing leg |

| Twist Lock | 4/8/10/12 pcs |

| Accessories | 1 waterproof tool box with stainless lock,2 spare tire carrier |

| Color | Any color will be available |

| Packing detail | Container ships |

Key parameters: 12 500 × 2 500 × 1 530 mm chassis, 3 mm chequered deck, three 13 t axles on leaf springs, 12 × 12 R 22.5 tyres, estimated 28 t payload at 39 t G.V.W.

The structural core is a cold-formed, single-piece “I” beam fabricated from Q345B structural steel. At 500 mm deep, with a 14 mm top flange, 16 mm bottom flange and 8 mm web, the section modulus reaches 1 050 cm³ per side rail—roughly 35 % higher than the light-duty 12 m platforms common in Asian intra-city work. This reserve of bending strength is intentional: it keeps flange stresses below 200 MPa when the trailer is hit with a 12 t point load from a 20 ft container corner casting on a potholed road. Finite-element studies commissioned by two Nigerian fleet operators show that peak stress occurs at the 0.4 L position (just ahead of the centre axle), exactly where the African specification places a 300 mm wide reinforcement plate. The same modelling exercise revealed that a European 10 mm web/12 mm flange design would exceed the yield limit at only 22 t payload under identical boundary conditions. In other words, the heavier African beam is not over-built; it is correctly built for the duty cycle.

Running gear follows an equally rational path. Three 13 t rated axles with 90 mm square spindles—usually FUWA or BPW commercial variants—give an aggregate GAWR of 39 t, aligning with the maximum legal gross combination mass in ECOWAS and EAC jurisdictions. Leaf-spring suspension is specified almost universally, not because it is intrinsically superior, but because repair knowledge and spare leaves are available within 50 km of any major corridor. Air suspension, although lighter, suffers from diaphragm embrittlement at 45 °C ambient temperatures and from the widespread use of detergent-laden water as emergency air-line oil. Tyre choice has likewise stabilised on 12 R 22.5 18-pr “mixed-service” patterns: the 1.2 m rolling circumference keeps engine speed down on 3.08 : 1 drive axles, while the 18-ply rating provides an extra 1 350 kg reserve load per tyre over the more common 16-pr regional-haul product. Fleet data from a Kenyan cement haulier show a 14 % reduction in tyre events per 100 000 km when moving from 16-pr to 18-pr, enough to offset the 4 % purchase-price premium within the first tyre life.

Lifecycle Economics and Regulatory Fit

The final reason for the specification’s dominance is economic. A 28 t usable payload at 39 t G.V.W. captures the full legal envelope in fifteen African countries that apply the 8 t single-axle and 11 t tandem-axle limits. Operators therefore avoid the revenue loss that lighter 24 t-capacity platforms impose, while staying compliant at roadside inspections that now use portable axle-load scales. Maintenance modelling over a 10-year horizon—1 200 000 km at 18 % discount rate—shows total cost of ownership (TCO) of USD 0.18 per tonne-kilometre for the steel-intensive specification, versus USD 0.21 for an aluminium-frame flatbed forced into early retirement by fatigue cracking around the fifth year. Residual value also favours the heavier unit: second-hand traders in Durban and Lome currently quote 38 % of purchase price at seven years of age, provided the main beam exhibits less than 5 mm permanent deflection. Achieving that durability target is, paradoxically, facilitated by the very mass that European designers try to eliminate: the thicker flanges raise the neutral axis, reducing peak tensile stress at the underside weld toe by 12 %. In a market where capital is expensive and steel is comparatively cheap, the African flatbed specification is therefore not a temporary workaround; it is a financially optimal, engineering-validated solution that is likely to remain the regional default for the foreseeable future.